Computer-Controlled Machining

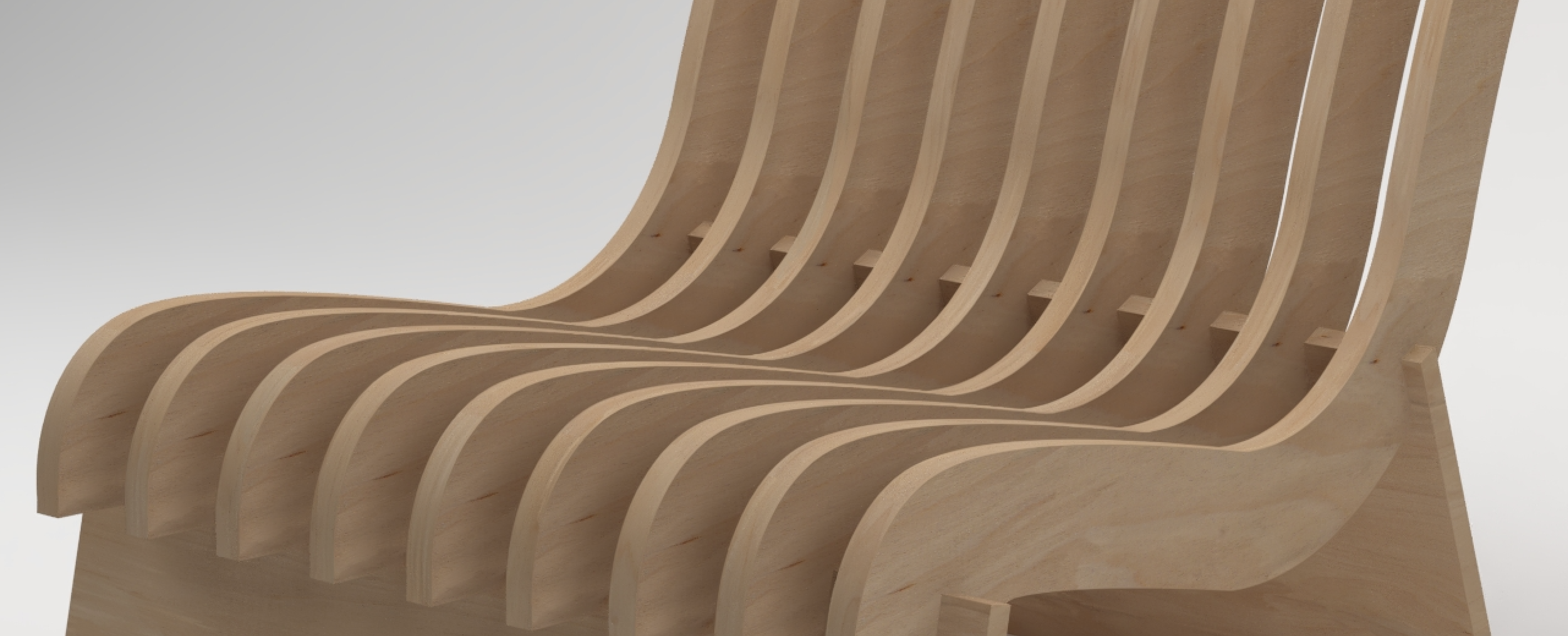

This project explores the design and creation of a modern, slotted wooden chair crafted entirely using a CNC milling machine. Inspired by minimalist aesthetics, the chair is designed with interlocking press-fit joints, emphasizing precision and efficient material use. The process integrates CAD modeling, advanced machining techniques, and careful assembly to produce a functional and visually striking piece of furniture that embodies modernity.

The Background

In Ancient Egypt, wood was a material used sparingly due to its scarcity in the region. The majority of construction and furniture-making relied on more abundant materials such as stone, mudbrick, and reeds. However, wood did play a significant role in the creation of items like furniture, boats, and tools, especially for the elite and in the construction of tombs and temples. The Egyptians typically sourced wood from imported regions, as the natural vegetation around the Nile was limited in terms of forested areas. Cedar, sycamore, and acacia were the most common types used. Woodworking in Ancient Egypt was a highly skilled craft, involving precise techniques for shaping and assembling materials. Chairs, particularly those found in the tombs of pharaohs, were often designed with symbolic and functional purposes in mind. The seats were usually low to the ground, with square or rectangular bases. They featured intricate carvings that depicted scenes of daily life or divine symbols, showing the owner's status. These chairs were typically built with a simple frame and reinforced with textiles or leather for comfort. The making of such furniture involved advanced craftsmanship, with skilled artisans shaping the wood, using tools such as chisels, mallets, and saws to create finely crafted, durable pieces.

I decided to make a wooden chair.

The Works

There’s a twist to this though, the Ancient Egyptian’s didn’t make press-fit designs and weren’t too fond of simple or minimalism. I decided to incorporate some Scandinavian furniture influences to aid me with the design. I had to create a layout and traces purely off of looking at a picture (there were no ready made designs for this).

From Photo to Points

Design Furniture: Examine the model found in the Swedish furniture catalogue, looking closely at the individual pieces that make up the chair.

Prepare Traces: Design into 2D outlines, optimize the layout, and export as DXF or SVG for milling.

Finalize Tool paths: Add dogbones, set cutting parameters, simulate the process, and export G-code for the milling machine.

Send it to Chris: He will evaluate its eligibility for the machine then get the process of the making started.

From Drawings to Wood

With the finalized drawings prepared as 2D outlines, we collaborated with the workshop manager, Chris, to load the design files into the CNC milling software. Chris guided us in selecting the appropriate router bits and adjusting the cutting parameters to suit the plywood's thickness and density. He meticulously set up the toolpaths, ensuring the design would be cut efficiently with minimal material waste. After securing the plywood sheet to the machine bed, Chris supervised the milling process, making adjustments to the feed rate and spindle speed to achieve a smooth and precise cut.

Once the milling was complete, we carefully removed each piece, and Chris provided tips on sanding the edges to eliminate any roughness or splinters left by the machine. With all components ready, we began assembling the chair, following the interlocking press-fit design. Chris suggested using clamps in certain areas to hold the pieces in place temporarily, ensuring a tight and seamless fit. His expertise and attention to detail were invaluable as we navigated minor adjustments during assembly, ultimately transforming the flat, milled pieces into a sturdy and elegantly crafted chair.

The Final Product

The final product is a modern, minimalist chair that showcases the precision and elegance achievable with CNC milling technology. Its slotted design, inspired by Scandinavian furniture aesthetics, combines form and function seamlessly. Each component interlocks with precision, forming a stable and visually striking structure without the need for adhesives or fasteners. The chair's flowing contours, milled from high-quality plywood, highlight the natural grain of the wood, giving it a warm and organic appearance that complements its contemporary form. The craftsmanship reflects not only the careful planning and execution of the design but also the thoughtful use of material, minimizing waste and maximizing structural integrity. The slight flexibility of the slats provides ergonomic support, offering comfort and functionality in equal measure. This project represents the intersection of traditional woodworking principles and modern digital fabrication techniques. The chair’s assembly process, driven by press-fit connections, emphasizes the importance of precision at every stage, from CAD modeling to milling and final construction. The finished product serves as both a functional piece of furniture and a testament to the collaborative process, combining design innovation with technical expertise. Its clean lines and modular construction make it versatile for various interior spaces, while its durable construction ensures longevity. The project not only met but exceeded its goals, achieving a balance of aesthetic appeal, structural efficiency, and material sustainability. This chair is a product of ingenuity and care, embodying the potential of CNC technology to transform a conceptual design into a refined and tangible object.

Vinyl Cutter

Using a vinyl cutter, I intricately crafted my name in elegant calligraphy, capturing each curve and flourish with precision. The design was meticulously planned to ensure clean lines and graceful details. I selected a rich, dark blue vinyl for a striking and sophisticated finish, allowing the calligraphy to stand out beautifully. The process involved careful adjustments to the cutter settings, ensuring the material was handled smoothly, and the final product showcased a perfect blend of artistry and craftsmanship.